By: Harry Whitehouse, IB Chief Innovation Officer

I am prompted to write this short narrative in response to the following two pictures that we received from US Postal Service Operations regarding the placement of shipping labels on packages. If you occasionally (or regularly) ship packages using any carrier (USPS, UPS, FedEx, DHL, On-Track, etc.), please stick with me for a few minutes.

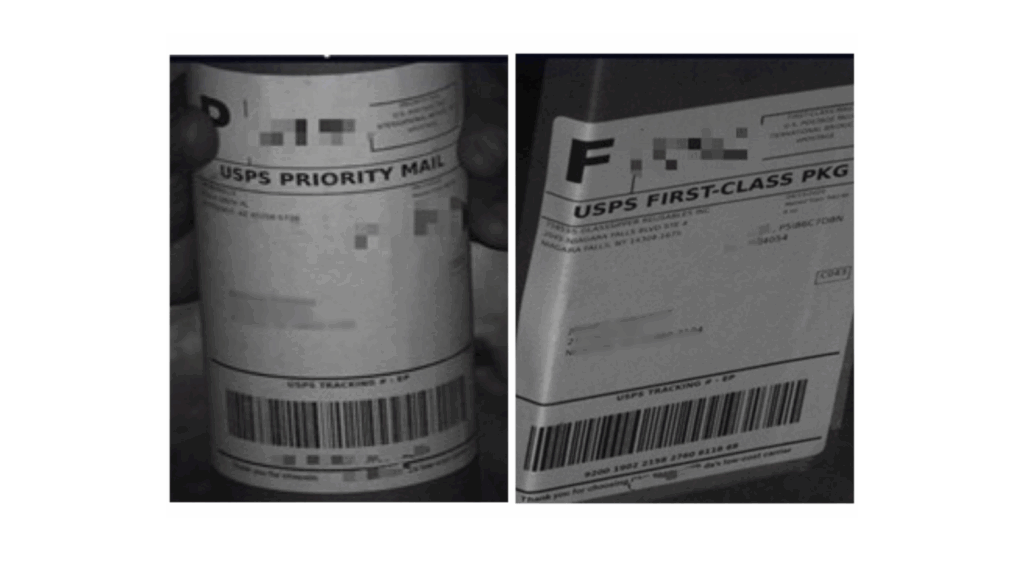

Tube Shaped Packages Rectangle Shaped Packages

These pictures show examples of label placements that essentially prevent the carrier from scanning your tracking barcode. Without these scans, neither you nor your recipient can “see” where the package is within the delivery cycle. You might even miss the all-important final delivery scan because a carrier may not have time to manually type 22+ characters into their handheld scanner when they are unable to automatically scan the package label.

This automatic scan fails because modern barcode scanners need to see the entire length of the one-dimensional barcode on a single planar surface. To put it another way, the barcode readers cannot easily read around corners. Fortunately, there is an easy fix for both situations.

For tube shaped packages, simply rotate the label by 90 degrees as shown here. Regardless of the relative position of the scanner and tube, there is always a portion of the barcode that is shown completely on one plane.

Additionally, the exposed height of the barcode is irrelevant. Modern scanners simply need a small slice of the barcode where the bars are on one plane and visible over the entire length.

For rectangular shaped packages, this issue can also be addressed by rotating the label 90 degrees. The barcode will still wrap around the corner of the package but in a way that still leaves two sections of barcode fully exposed and on the same planar surface.

If you regularly deal with very small packages, check to see if your postage label provider has a 4” x 4” label option; this smaller label format often makes a world of difference when placing labels on smaller packages.

And finally, if you are apprehensive about reducing the available height of the barcode, a bit of barcode history might help ease your concerns. The original one-dimensional barcodes required substantial heights (typically ¾” or 20 mm) because, in the early days, operations team members only had hand-held “pen scanners” rather than laser scanners. These pen scanners required that you move a pen-like device from one end of the barcode to the other. If the barcode is more than a few inches long, your arm and hand would naturally travel in a slight arc. To accommodate that arc, barcode heights were set to generous levels. But with the laser scanners used today, that generous height is not needed.

Happy shipping!

For other great shipping tips or to find out more about the cost savings you can enjoy while using blue™, visit us at www.myib.com/blog or contact us today at sales@myib.com.